Product information

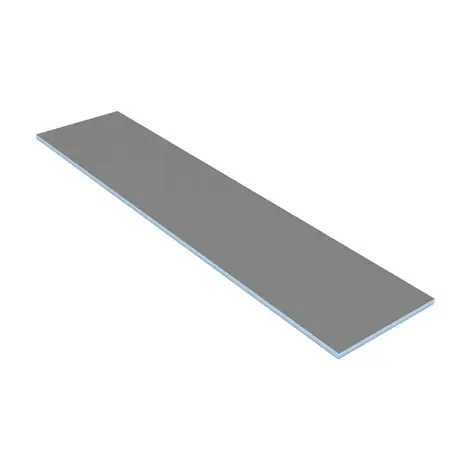

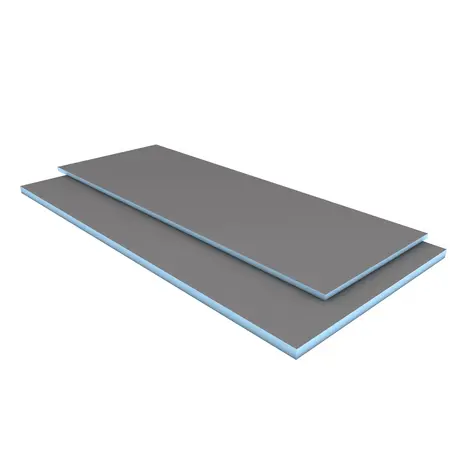

Highly polymer-modified, hydraulic and quick-drying middle bed mortar for walls and floors, mortar bed thickness of 5 – 20 mm, for indoor use, waterproof. Tested as C2 FT under DIN EN 12004.

- highly plastic-coated, hydraulically and quickly setting middle-bed mortar for wall and floor coverings

- mortar bed thickness of 5–20 mm

- for Indoor use

- waterproof

- C2FT-tested according to DIN EN 12004

- suitable for underfloor heating

Technical Details

| Technical properties | |

|---|---|

| Mixing ratio | approx. 5.5 litres of water to 25 kg of powder |

| Processing time | approx. 50 minutes |

| Tile application time (open time) | approx. 15 minutes (depending on absorbency and temperature) |

| Realignment time | up to approx. 10 minutes (depending on absorbency and temperature) Hard enough to walk on/grout after approx. 5 hours |

| Fully load-bearing | after approx. 2 days |

| Suitable for underfloor heating | |

| Processing (air) temperature | mind. +5°C, max. +30°C |

Downloads

Usage

Surface requirements

All surfaces must be solid, load-bearing, even and non-deformable. They must be free of dust, dirt, loose objects and separating agents such as oil, grease, wax, varnish and paint. All absorbent, mineral surfaces (powdery cement plasters, gypsum plasters, anhydrite screeds etc.) must be primed with primer. Any sinter layers must be removed first. Comply with DIN 18560.

Smooth, non-absorbent surfaces (e.g. old tiles) and old paint, carpet adhesive etc. that cannot be removed must be primed with adhesive and contact primer.

The current ZDB information sheets on floor coverings on heated floor structures must be observed when bonding to screeds with underfloor heating.

If in doubt, test in an inconspicuous corner!

The residual moisture content must not exceed the following values:

Cement screeds: 2.0 %

Calcium sulphate screeds: 0.5 %

Heated calcium sulphate screeds: 0.3 %

Gypsum based plasters: 1.0 %

(measurement with CM instrument)

Magnesite-based screeds must be primed using epoxy resin primer.

Processing:

Add 25 kg of powder to approx. 5.5 litres of cool water in a clean container and mix vigorously and evenly (spiral mixer) until a smooth, lump-free mortar is formed. Allow the mixture to mature for at least 3 minutes. Then stir it again. At a normal temperature the processing time is approx. 50 minutes.

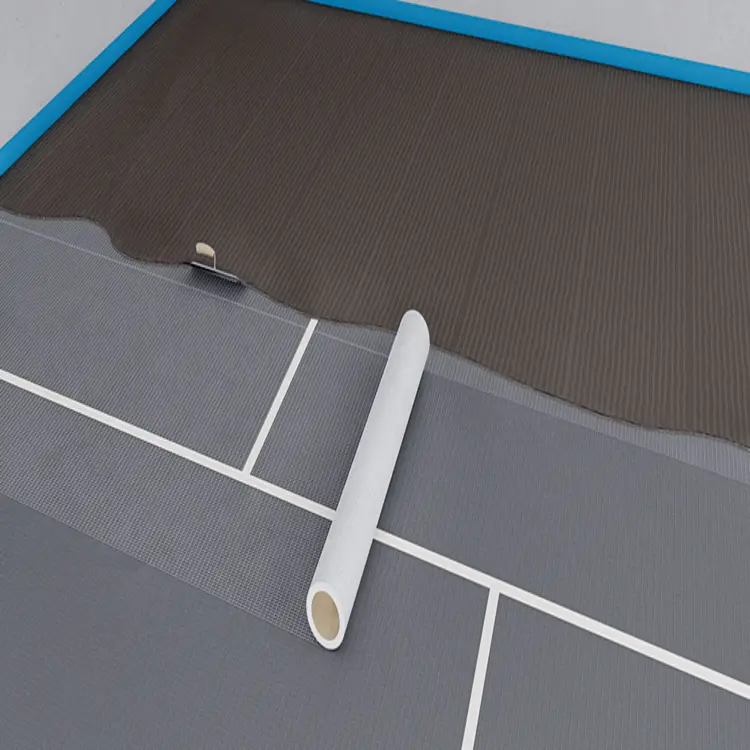

First apply wedi 360 with a smoothing spatula to form a contact layer on the surface and spread it evenly using a smoothing trowel. Then use a grooved middle bed trowel to apply/comb on more mortar to ensure full-surface bonding of the covering. The quantity of mortar applied and the area to be laid must be adapted to the absorbency of the surface and the air temperature. The open time before a skin forms is approx. 15 min.

Under no circumstances must the mortar bed be allowed to form a skin (test with your finger). Depending on the absorbency of the tiles, they can be realigned for up to approx. 10 minutes (realignment time).

Hard enough to walk on and grout after not less than approx. 5 hours.