Product information

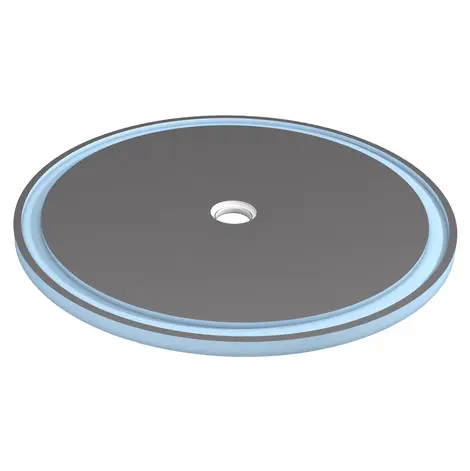

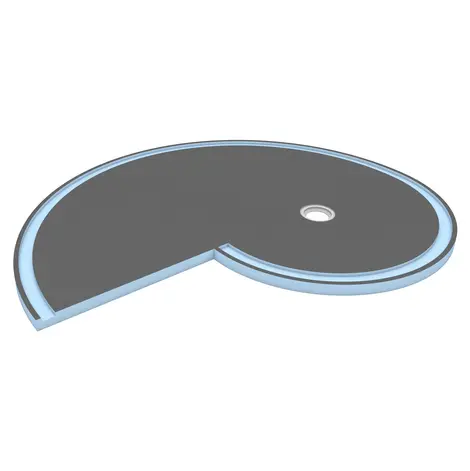

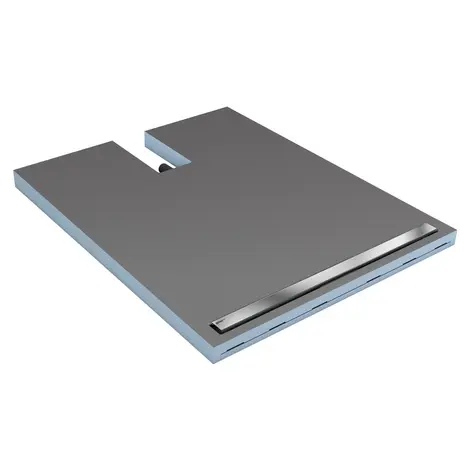

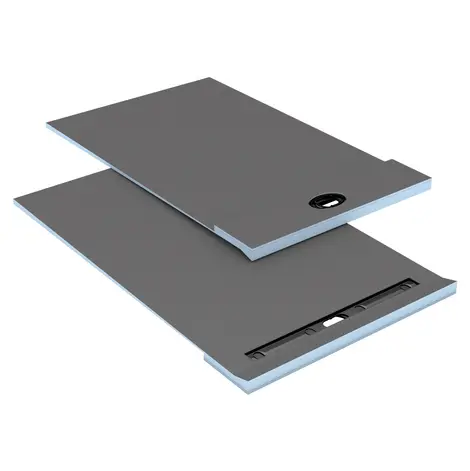

wedi building board systems

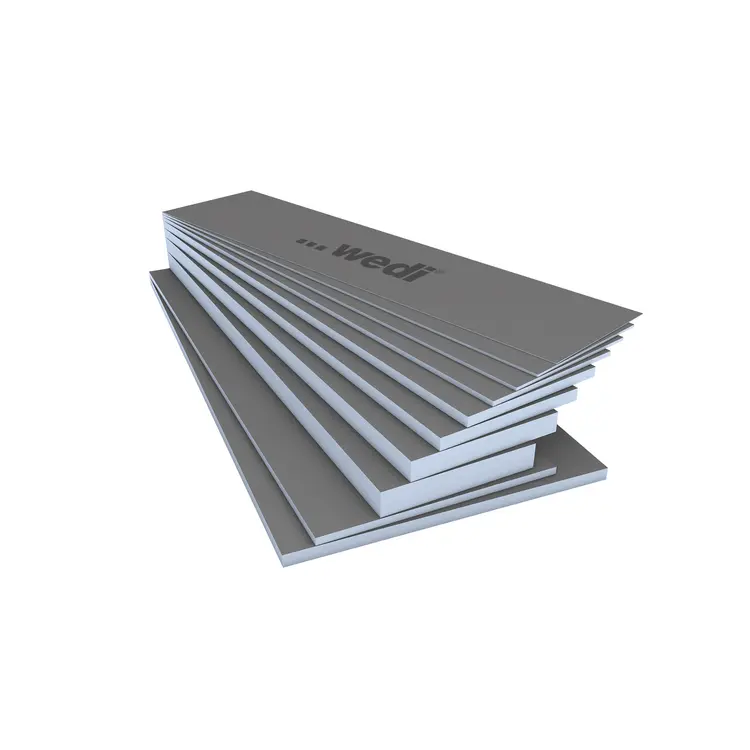

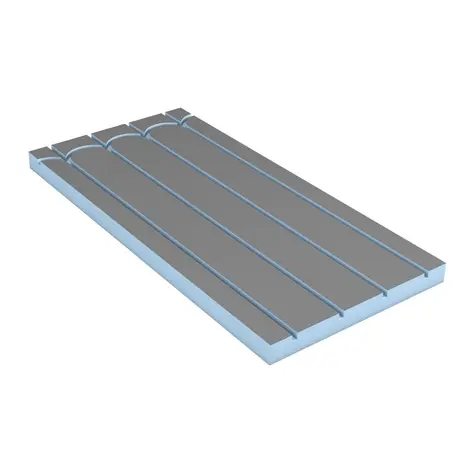

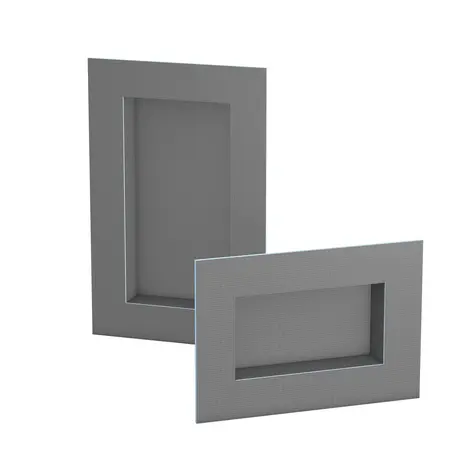

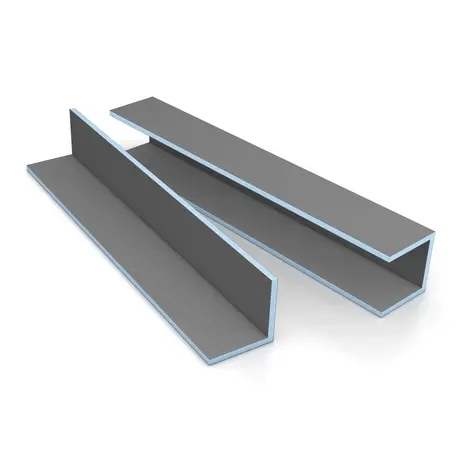

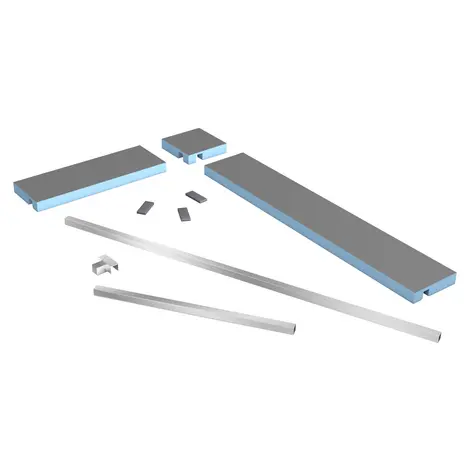

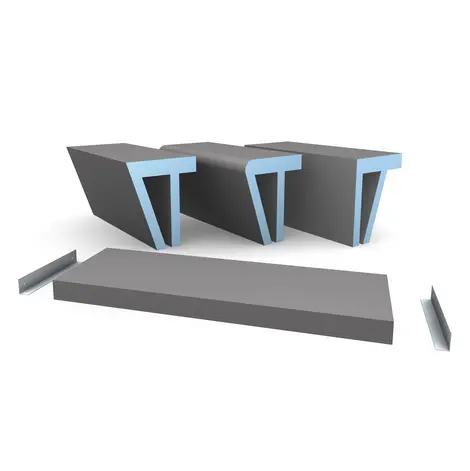

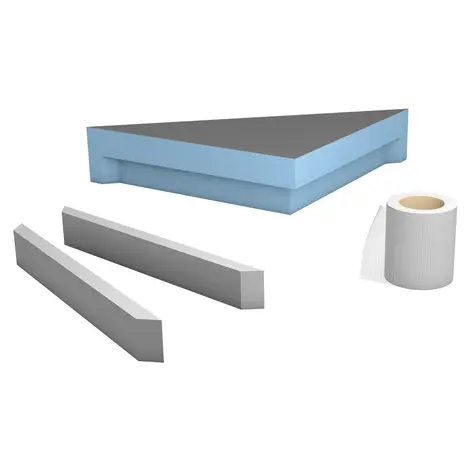

wedi building boards have a blue core made from CFC-free extruded polystyrene rigid foam. This makes the wedi building board an ideal basis for any type of plaster and tile. wedi building boards can be applied to practically any substrate, are waterproof, insulating, versatile, light and robust.

- The blue XPS core is 100% waterproof and remains fully functional even after possible damage.

- abP*: building board butt joints can be sealed 100% simply by using wedi 610. As no other seal is necessary, craftsmen benefit from increased security accompanied by a shorter tiling time.

- The cemented surface is a good adhesive under-surface. The fibre fabric also absorbs tensile forces.

- All building board systems have great heat insulation properties,

Energy efficient

Excellent thermal insulation properties even at low strength

Hygienic

Protection against mold and fungal growth

Field-tested

The original pioneers, successfully leading the way for 40 years

Reliable

100% Waterproof from 2mm thick XPS core

Fast

Balances uneven walls, directly tileable

What must be observed when preparing the substrate?

This content is provided by YouTube. By loading this content, you consent to the transfer of your data to YouTube / Google. You can find more information about this here:

Google Privacy.

Technical Details

| Technical data of building board | |

|---|---|

| Sound insulation DIN EN ISO 140-3 (at board thickness of 12.5 mm) | Rw, P 23 dB |

| Fire behaviour EN 13501 | E |

| Bending stress based on DIN 53293 | 3900 kPa (mean value) |

| Adhesive tensile strength | 0,28 N/mm2 |

| Weight: wedi building board (1250 x 600 x 4 mm) wedi building board XXL (2500 x 1200 x 50 mm) | 2,7 Kg 13,8 Kg |

| Linear coefficient of thermal expansion | 0,02 mm/(mk) |

| Technical properties – Rigid foam | |

| Long-term compressive strength (50 years) ≤ 2% compression EN 1606 | 0,08 N/mm2 |

| Compressive resistance or compressive strength at 10% compression EN 826 | 0,25 N/mm2 |

| Associated modulus of elasticity EN 826 | 10 – 18 N/mm2 |

| Thermal conductivity EN 13164 | 0,036 W/mK |

| Tensile strength EN 1607 | 0,45 N/mm2 |

| Shearing resistance EN 12090 | 0,2 N/mm2 |

| Shear modulus EN 12090 | 7 N/mm2 |

| Bulk density EN 1602 | 32 kg/m3 |

| Resistance to water vapour diffusion(μ) EN 12086 | 100 |

| Water absorption under long-term immersion EN 12087 | ≤ 1,5 Vol.-% |

| Capillar action | 0 |

| Linear coefficient of thermal expansion | 0,07 mm/mK |

| Temperature limits | -50°C / +75°C |

| Fire behaviour EN 13501 | E |

| Propellant gas, carbon dioxide, GWP value | 1 |

Usage

- The possibilities are endless when it comes to wall, floor not least because of the wide range of different thicknesses.

- They can be applied to practically any type of substrate. Whether it's old tile coverings, adhesive or non-adhesive substrate, lush mounting onto existing plasterboard or dry lining. Thanks to the simplified processing, wedi building boards can handle all manner of challenges on the building site.